End Mills – Carbide Tapered | Carbide | Atlas Cutting

Special Tooling. Don''t see what you are looking for or require special tooling? We can help! Our dedicated team can provide quotes for custom tools and guidance for multiple job applications!

WhatsApp)

WhatsApp)

Special Tooling. Don''t see what you are looking for or require special tooling? We can help! Our dedicated team can provide quotes for custom tools and guidance for multiple job applications!

Measure It! Micrometers, Calipers, Dial Indicators, Gages We stock the measuring tools you need for precision metalworking . Cut It! Drill Bits, End Mills, Reamers, Saw Blades We have high speed steel and carbide tools to cut and shape your work.

Noncentercutting End Mills are suitable for peripheral milling and finishing, but cannot be used to make plunge cuts. HSS and Cobalt End Mills will specify if they are center or noncenter cutting. Atlas Cutting Tools end mills offer a variety of coatings. Some end mills are uncoated, while others are coated with finishes to enhance performance.

With the increase in Mold and Die manufacturing in the North American market, there is a growing need for a full metric range of MBZ215 and MZN410R/510R products from Niagara Cutter™. Because of this, we have expanded the range to include ball nose end mills from mm up to 12 mm in diameter and high feed end mills from 2 mm up to 12 mm in

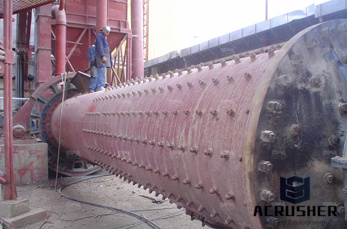

Carbide Tapered End Mills. Taper mills or "conical mills" produce grooves, holes, or milled sides with a sloped angle. They are used specifically for designed parts that require an angled side wall.

to identify an unknown thread, certain tools and data are necessary. included in these charts are a helpful compilation of the data needed for the identification of most external (male) threads from the three most popular thread systems in the world, metric standards, (inch) standards, and .

OSG offers drills, taps, end mills and indexable cutting for a wide variety of applications

This feature gives the taper tap a very gradual cutting action that is less aggressive than that of the plug tap. The number of tapered threads typically ranges from 8 to 10. A taper tap is most often used when the material to be tapped is difficult to work (, alloy steel) or the tap is of a very small diameter and thus prone to breakage.

With 17 taps and 17 dies in a full range of coarse and fine sizes from 3 to 12 mm, the TEKTON Tap and Die Set (39Piece) is the ideal allpurpose set for your garage or shop. These tapered plug taps and

The 2017 Conical Tool catalog featuring our line of highspeed steel and carbide end mills, tapered end mills and specialty cutting tools. Request for quote and technical information is also available for download, and we will be adding other materials as they become available.

Metric End Mills Carbide. Metric mills have metric sized cutting diameters and shanks. They are commonly used in automotive, and aerospace milling applications. They are available in general purpose and high performance geometries. Our complete catalog of metric end mills is listed below.

OSG offers square, roughting, ball nose, corner radius, tapered and double end end mills, as well as routers and burs.

Tapered End Mills Built For Strength. These tapered end mills were designed to give our customers the ability to cut very fine detail and maintain tool strength. It is well known that the smaller the tip size the weaker the tool, but because these end mills ''taper out'' they will have much more strength.

mm Shank Diameter. Inch. mm. Length of Cut ... Tapered end mills are made from a variety of materials that are chosen according to the degree of precision, hardness, durability and wear resistance required by your application. ... They are used in several die and mold applications. ...

Solid Carbide Circle Segment end mills with Taper Form that can simulate a 250 to 500 mm radius cutter Low vibration machining 2 or 3 flute construction Flute form tolerance = ± mm Suitable for all most all materials ALCR multilayer PVD coating for heat and wear resistance Form A: allows up to 45˚ tilt angle Form B: allows more than 45˚ tilt angle for flat areas

Award winning carbide endmills, tapered end mills, custom end mills and milling / cutting tools at Conical Tool . Sameday shipping on all in stock items. Award winning carbide endmills, tapered end mills, custom end mills and milling / cutting tools at Conical Tool . Sameday shipping on all in stock items. ... Die Sinks. 3° 5° 7° General ...

Lakeshore Carbide is the leading distributer of high quality USA made carbide end mills, thread mills, gages, drills, solid carbide mills and chamfer mills at the lowest prices.

Carbide Taper End Mills of OSG, Check out the variety of configurable, Carbide Taper End Mills of OSG for industrial has other mechanical components, Press Die, and Plastic Mold products available. MISUMI offers free CAD download, short lead times, competitive pricing, and no minimum order quantity. Quote and order online today!

Solid Carbide Taper End Mills by AB Tools, Inc. Special orders in 46 working days. Proudly made in the USA by AB Tools, Inc.

2 flute (square end) single end mills metric page 264. 2 flute (square end) miniature single end mills regular length page 264. ... 3 flute (square end) tapered single end mills solid carbide page 277. single end mills 4 flute. ball nose. ... die sinking cutters page 277. double angle milling cutters page 284. dovetail cutters ...

Helical is a leading manufacturer of high performance carbide end mills and custom cutting tools. Find your local cutting tool distributor.

Tapered End Mills are center cutting, 3 flute high speed steel tools designed for side milling, contouring and machining angled slots. Ideal for use in die cast dies molds. Solid carbide models are precision ground and inspected to insure complete uniformity and reliability required in the precision mold industry. Available TiAlN coating withstands high heat, allows faster cutting ...

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power male member of conical form (that is, with a taper) fits into the socket, which has a matching taper of equal angle.. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools.

When one end wears out, switch to the opposite end for two times the life of a standard cobalt steel end mill. With better heat and wear resistance than highspeed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as cast iron, hardened steel, titanium, and tool steel.

WhatsApp)

WhatsApp)