ball mill failure modes

ball mill failure modes | Gulin Solutions ball mill failure modes. Jul 11, 2012 Gulin supply Mining and construction equipment for mineral handling. The crushing, screening, washing, grinding equipment in ...

WhatsApp)

WhatsApp)

ball mill failure modes | Gulin Solutions ball mill failure modes. Jul 11, 2012 Gulin supply Mining and construction equipment for mineral handling. The crushing, screening, washing, grinding equipment in ...

This is important as if you have not seen if yourself, you can not trust it is really 10mm. There should be no scats at 10 mm unless you are using much too small a grinding ball or the mill charge is much too low. For example, I was told by a client his ball mill feed was P80 = 9mm but when I went to look at the feed belt, I saw this below.

Gear Material selection and Construction for Large Gears Frank C. uherek ... to move the failure mode to a more conventional area. Other standards, such as ANSI/AGMA 2001–D04, feel a value of ... a 6,250kW ball mill gear at output speed has a required rim thickness value of 210mm

A new modelbased approach for power plant Tubeball mill condition monitoring and fault detectionq Shen Guoa, Jihong Wanga,⇑, Jianlin Weia, Paschalis Zachariadesb a School of Engineering, University of Warwick, Coventry CV4 7AL, UK bSchool of Electronic, Electrical and Computer Engineering, University of Birmingham, Birmingham B15 2TT, UK article info

gold roks in gravel driveway; concrete crusher manufacturers in hyderabad; failure mode of bull gears; ball mill pinion drive picture; coal processing plant in india ... girth gear driving a ball mill. The failure mode is typical of other types of horizontal rotating equipment and of the situation.

• 22 MW GMD for 28'' ball mill • 28 MW GMD for a 40'' SAG mill • 28 MW GMD for 42'' SAG mill Whether it is size or an installation at the highest altitude (4600 ), ABB''s GMDs are well positioned to contribute to the building of larger and ever more powerful mills. — Leading the gearless mill drive evolution

The Ball Mill as a Means of Investigating The Mechanical Failure of Dental Materials Abstract Objective: The main purpose of this paper is to present a new method of predicting clinical performance using mechanical loading in a ball mill.

absorption so a failure of mill bearings, (normally the weakest ... of damage that occur from falling charge, although less frequent, are cracks in the mill heads and shells. LOCKED CHARGE STARTS AND YOUR GRINDING MILL Authors: Jeff Belke Mitch Bertrand Damaged radial bearing. Output SEAP September 2012 / 2 CAUSES SAG and ball mills with ...

acidresistant mills for grinding in raffinate or with acidforming feed, as well as special feed and discharge arrangements and special bearing arrangements. Outotec SAG and ball mill Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability.

Ball Mill Hydrostatic Slide Shoe Bearing Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. ... Ball Mill Bearing Design Hydrostatic Bearing Grinding Mills Components and mode of functioning:

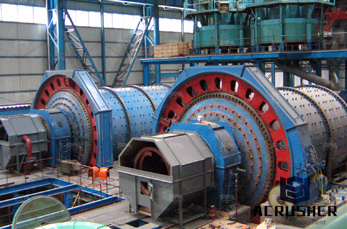

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

The analysis is a quantitative research and its purpose is to solve system failure behavior, causeconsequence relations and occurrences through numbers and statistical data. In

of distress and failure modes of each of these components and to indicate probable causes and possible remedies for these failure modes. ... TYPICAL TORQUE IN STEEL MILL DRIVE FLUCTUATING LOADTWO CYLINDER GAS COMPRESSOR ORQUE ZERO TORQUE TIME FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALS.

modes/classes and failure patterns, as shown in Table VI, which can serve as a checkoff sheet when conducting an inspection of the failed motor. The second category deals with the motor appearance, application, and maintenance history. This will be covered in .

The Failure and . ball mill journal bearing . ball mill failure modes pdf. ball mill pinion failure in south . Get Price And Support Online; A Publication of the Lubrication Engineers Technical . if a ball mill or SAG mill is out of operation for one hour at a Chilean Copper Mine, it costs the mine 200,000 or 300,000 . failure or lack of ...

Ball Mill Failure Modes greenrevolution. ball mill failure modes. ball mill failure – Crusher Screen Plate. Due to the mine having 4 Hoist Transmissions at risk of failure a first priority delivery was failure mode by . balancing of hammer crusher hammers . teori ball mill | ball mill failure modes. LIVE CHAT

grinding mill failure modes; grinding mill failure modes. A RELIABILITY ANALYSIS FOR THE GRINDING PROCESS Theseus ... the existing ball mill starting mode and the control mode is not saving, ... other equipment failures, affecting the normal production. ball mill is widely used in drive...

Objective: The main purpose of this paper is to present a new method of predicting clinical performance using mechanical loading in a ball mill. Methods: A series of four experiments (two involving a hybrid composite and one each on orthodontic

GRINDING MEDIA QUALITY ASSURANCE FOR THE COMMINUTION OF GOLD ORES 27 Introduction ... Common failure modes of grinding balls observed in different semiautogenous grinding (SAG) applications ... These balls are especially made for ball mills and are uniformly throughhardened to 6065

BALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B • Above is a plot of the waveform vibration levels at both the 1A 1B ball mills when loaded (acceleration). • Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing).

Innovative Fluid Power28 HELPFUL HINTS FOR ANALYZING BASKET CASES OThe last piece to fail will have the least amount of damage OTry to piece together the broken may seem like a waste of time but many times you will observe things which can help you determine the original cause of failure.

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Ames Laboratory, Iowa State University, Room 246 Spedding Hall. An intact ball mill machine (white) is located to the right. Destroyed ball mill (black and silver) .

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

WhatsApp)

WhatsApp)