ball mill working principle YouTube

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

WhatsApp)

WhatsApp)

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

Grinding Services Business Directory, India Business Directory Job Work for Slide Way Grinding Machine....With portable in situ crankshaft grinding equipment our technicians come to your works or vessel to ..... Following the same principle, the mechanical motion of these shafts of the grinding .

There are 115 grinding machine working principle suppliers, mainly located in Asia. The top supplying country or region is China, which supply of grinding machine working principle respectively. Grinding machine working principle products are most .

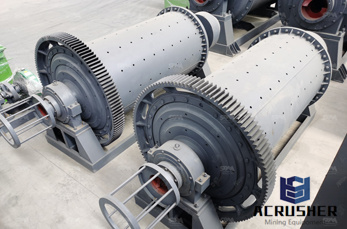

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by .

Ball Mill Working Principle And Main Parts GitHub Pages. Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on ...

May 20, 2019· Grinding Machine working principle. Grinding wheel. The grinding machine is a complex operation machine but easy to use. First of all, so that it receives energy, the electromagnet must be activated. The electromagnet will be in charge of holding the piece and will not move.

Working principle of drilling machine Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Working principle of drilling machine, quarry, aggregate, and different kinds of minerals.

principle of working of grinding machine YouTube. Feb 6, 2014, grinding machine working principle ppt binq miningjaw crusher working principle ppt this page is provide professional jaw crusher working. Contact Supplier. Industrial Machinery Safety Occupational Safety and Health,

Working principle. In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a workholding platform. One wheel, known as the grinding wheel (stationary wheel in the diagram), is on a fixed axis and rotates such that the force applied to the workpiece is directed downward, against the workholding platform.

reamed, or bored hole, using small grinding wheels at high RPM. The principle elements of a internal grinding machine are the workhead, which holds the work and has its own drive; and the wheelhead, which is the internal grinding spindle. In addition to the rotary motions of work and wheel, an internal

working principle of grinding machine | worldcrushers. May 06, 2013· Grinding Machines (4) . vertical roller mill working principle . grinding mill is the newest grinding machine . Hydraulic Impact Crusher; Grinding Mill Series. grinding machine working principle ppt – BINQ Mining

Jaw Crusher Working Principle Ppt; ... Barite grinding machine germany. barite grinding machine germany chinatruckpartscoza grinding machines for barite celebration cakes barite grinding machine germany is manufactured from shanghai it is the main mineral mining in mexicocrushinggrinding machines for ba . remove crushing machine from germany ...

Working principle of grinding machine Crusher . Guidelines part 2d grinding machines. what is the working principle of milling machine? the workpiece is holding on the worktable of the machine. the table movement ...

ppt of principles of grinding. principle of working of grinding machine – 6 Feb 214 grinding machine working principle ppt – binq miningjaw crusher working principle ppt this page is provide Ball mill – Wikipedia, the free encyclopedia A ball mill is a type of grinder .

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand.. In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding ...

Jul 07, 2015· WORKING PRINCIPLE 34. CENTERLESS GRINDING MACHINE 35. e. Internal grinding machine In this type the grinding is done in the internal side of work piece. In this operation the work piece may rotate or may not be rotate. It can be done on different internal surface like straight, tapered, grooved, or profile. 36.

Grinding is a term used in modern manufacturing practices to describe machining with highspeed abrasive wheels, pads, and belts. Grinding wheels come in a wide variety of shapes, sizes, and types of abrasives. In recent decades, grinding has been evolved both for producing very high quality parts and for fast economic production.

Cylindrical grinder Wikipedia, the free encyclopedia The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work .

working principle of grinding machine working principle of hammer mill The working principle of hammer mill is using the high speed rotary more oven feeds, recent work has Wood Hammer Mill Working Principle There are .

Make sure that you unplug power from the grinder prior to performing any work to the grinder. Make sure that the bench grinder is located on a sturdy and stable bench or pedestal specifically made to support the bench grinder. 26 Bench Grinder. Using Bench Grinder ; Turn on grinder and let the grinding wheels reach

Grinding machine is a power operated machine tool where, the work piece is fed against constantly rotating abrasive wheel to remove thin layer of material from work. 10 Principle of grinding machines. Work piece is fed against the rotating abrasive wheel. Due to action of rubbing or friction between the abrasive particles and work piece material is

Oct 15, 2014· SURFACE GRINDING MACHINE 14. Surface Grinding machine 15. CYLINDRICAL GRINDING MACHINE FIG. PRINCIPLE OF CYLINDRICAL GRINDING Principle: The work piece is held between two centers and the rotating grinding wheel is fed against it. External Grinding machine Work Piece Type: Cylindrical surfaces may be straight, curved or contoured.

UNIT 6: Grinding machines: Types of abrasives, bonding process, classification, constructional features (cylindrical and surface grinding), Selection of grinding wheel. 6 Hrs Instructional Objectives: At the end of this lesson the students would be able to Understand basic principle of grinding. Recognize purpose and application of grinding.

Centreless (Centerless) Grinding Principle. ... However this low point must not be exactly in the opposite side of the work piece. The grinding machine has to be set up in a way that a polygon form is ground with so many corners that it is almost round finally. g: ... (centerless) Grinding Machines.

WhatsApp)

WhatsApp)