193 Ball Mill Dr, Perryville, MO 63775 ®

View 36 photos for 193 Ball Mill Dr, Perryville, MO 63775 a bed, bath, acres. single family home built in that sold on 05/10/2016.

WhatsApp)

WhatsApp)

View 36 photos for 193 Ball Mill Dr, Perryville, MO 63775 a bed, bath, acres. single family home built in that sold on 05/10/2016.

The ball mill motor power requirement calculated above as 1400 hp is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution the following shows how the size or select the matching mill required to,What is cement mill main drive.

What is Ball Milling? Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber.

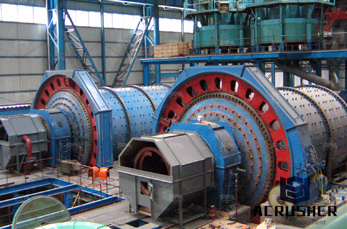

A ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials that has the same goal as other grinding machinery and crushing machinery. We produce components used in Ball Mills for the following Industry.

4 series planetary ball mill main belt tightness adjustable, longterm use is not easy to slip, greatly extended the service life. 5 the series of planetary ball mill appearance original box clamshell (or open), easy to operate, cover with safety switch, safe and reliable. 6 series planetary ball mill adopts the complete rolling friction drive between the metal wheel and the abrasive wheel.

The mill used for this comparison is a diameter by meter long ball mill with a 5000 HP drive motor. It is designed for approximately 90 per hour. This type twocompartment mill is a state oftheart shell supported cement finish mill. The torque and time requirements of the mill with the ball

Homemade DoubleBarrel Ball Mill Ball milling replaces potentially unsafe hand grinding of chemicals and compositions. The crushing of the material is accomplished by the repeated falling of heavy balls onto it, over and over, inside the mill jar. So, it sounds like I need a ball mill.

Ball mill with COMBIFLEX® drive for lead zinc ore grinding. ... current and the load of the mill drive train. how to align ball mill pinion to drive motor :201293inner rotation and outerlevorotation nce the pinion of the ball mill rotate with the motor, to balance the load, the motor of the ball mill use the zero ...

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Ball Mill Drive Options. At Orbis Machinery we offer a variety of drive options to suit your needs: Standard shaft mount reducer and belt drive; Gearwheel and pinion

Jun 20, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball Charge

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential features of a model for mill .

The SAG mill is followed by two 20ft diam., 7,500hp geardriven ball mills. Another type of drive, less commonly used, consists of a motordriven speed reducer that is coupled to one of two ...

Jun 22, 2018· The ball milling method consists of balls and a mill chamber. A ball mill contains a stainless steel container and many small ball made up of iron, hardness steel, tungusten carbide, or .

Horizontal Ball MIll Drives. We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual components as required. • Mill drive gearboxes • Girth gears • Pinions • Couplings.

Ball Mill With Central Drive Poole''s Mill Park Parks 7725 Poole''s Mill Rd, Ball . 5 reviews of Poole''s Mill Park "Great spot to spend the day with kids sliding down rocks and small rapids, or just chilling in the still waters at the top.

Choice Of Ball Mill Drive. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Oct 12, 2017· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

Our ball mills are industrial grade and designed for continuous operation, equipped with oversize roller bearings and a complete drive system. All wear parts are highly abrasion resistant and replaceable. The capacity, or throughput, of a ball mill, is directly linked to particle size of the ball mill discharge.

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the Sepro tyre drive Grinding Mill. Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, drawing approximately % of the total world''s power (see List of countries by ...

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing to produce the world''s largest SAG mill of 42'' in diameter drawing power at 28 MW. Today, is the world leading supplier of gearless SAG mills operating globally.

auxiliary drive, is an important component of any mill or kiln installation. It is used for maintenance and inspection purposes, as well as an emergency auxiliary drive to keep kilns rotating when the main motor fails. This paper covers what data the end user needs to

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

ABB''s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ''workhorse'' for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability .

WhatsApp)

WhatsApp)